Formulation and Delivery - Chemical

(M1030-09-56) Personalized 3D-Printed Tablets for Diabetes and Related Complications: Design, Optimization, and Evaluation

- TA

Thirupathi reddy Anekalla, MS

Research Assistant and Event manager of AAPS Student Chapter at University of Mississippi

University of Mississippi

Oxford, Mississippi, United States - TA

Thirupathi reddy Anekalla, MS

Research Assistant and Event manager of AAPS Student Chapter at University of Mississippi

University of Mississippi

Oxford, Mississippi, United States - SB

Sujith raj Bashetty, MS (he/him/his)

Research Assistant and President of AAPS Student Chapter at University of Mississippi

University of Mississippi

Oxford, Mississippi, United States - NN

Navya Nalajala, MS

Research Assistant and Secretary of AAPS Student Chapter at University of Mississippi

University of Mississippi

Oxford, Mississippi, United States - NN

Nagarjuna Narala, MS (he/him/his)

PhD Student

University of Mississippi

Oxford, Mississippi, United States - TA

Tejaswi Appidi

Graduate student

University of Mississippi

Oxford, Mississippi, United States

Jaidev Chakka, Ph.D.

Post-doc

University of Mississippi

Oxford, Mississippi, United States- MM

Mohammed Maniruzzaman, Ph.D.

Professor

University of Mississippi

Oxford, Mississippi, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Methods: Pneumatic-based thermoplastic 3D printing was employed to fabricate bilayer tablets combining two Biopharmaceutical Classification System (BCS) model drugs. Eudragit RSPO was used as an extended-release polymer for Metformin HCl, and PEO N10 was employed for immediate release of Atorvastatin Calcium. The formulations were optimized for printability, mechanical integrity, and drug release using excipients such as PEG 3350, Pluronic F127, and sorbitol. The tablets were evaluated for physical characteristics, thermal behavior (DSC), crystallinity (XRPD), molecular interactions (FTIR), surface morphology (SEM), drug content (assay and HPLC), and in vitro drug release. Mass spectrometry was used to confirm the chemical integrity of the APIs post-printing.

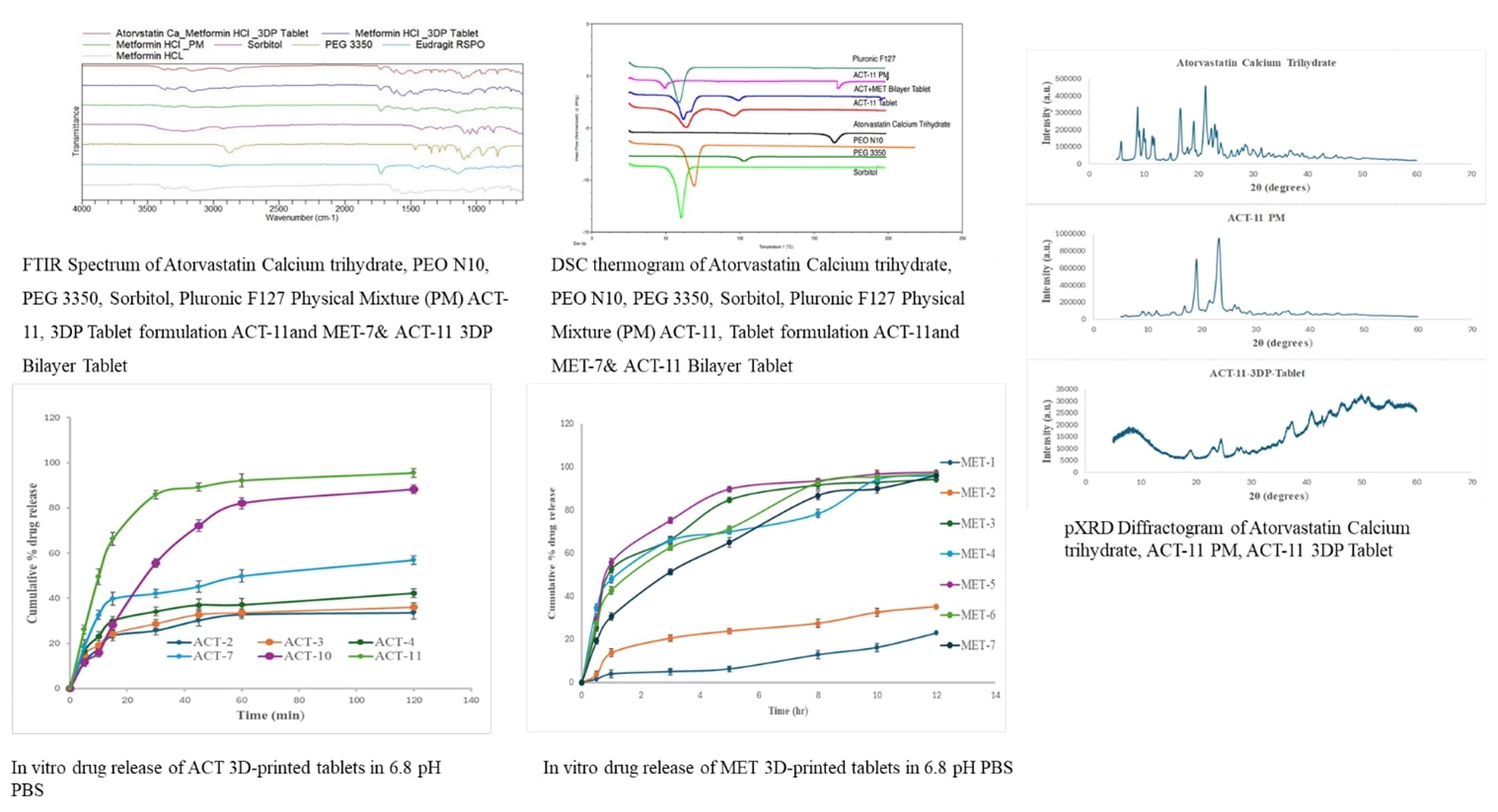

Results: The optimized Metformin formulation (MET-7) achieved extended drug release, reaching 89.71% at 10 hours and meeting USP specifications. The Atorvastatin formulation (ACT-11) released 89.54% of the drug within 30 minutes, confirming suitability for immediate release. XRPD and DSC analyses indicated partial amorphization of Atorvastatin during printing, enhancing solubility, while FTIR showed no drug–excipient interactions. SEM analysis revealed well-layered structures with consistent morphology. All formulations met USP requirements for assay and content uniformity, and mass spectrometry confirmed chemical stability of both drugs post-printing.

Conclusion: The study demonstrates the feasibility of using pneumatic-based DPE 3D printing to fabricate bilayer tablets with distinct release profiles, combining Metformin and Atorvastatin in a single dosage form. This single-step, solvent-free printing method enables personalized drug delivery, reduces pill burden, and offers a promising platform for producing polypills targeting chronic conditions such as diabetes and cardiovascular disease.

References: Alqahtani MS, Kazi M, Alsenaidy MA, Ahmad MZ. Advances in Oral Drug Delivery. Front Pharmacol [Internet]. 2021 Feb 19 [cited 2025 Apr 14];12. Available from: https://pubmed.ncbi.nlm.nih.gov/33679401/

2. Alhnan MA, Okwuosa TC, Sadia M, Wan KW, Ahmed W, Arafat B. Emergence of 3D Printed Dosage Forms: Opportunities and Challenges. Pharm Res [Internet]. 2016 Aug 1 [cited 2025 Apr 14];33(8):1817–32. Available from: https://pubmed.ncbi.nlm.nih.gov/27194002/

3. Maniruzzaman M, Robert C-S, Williams O, Zhengrong C-S, Debadyuti C, Kun G, et al. Novel 3D bioprinting of biomaterials : application of statistical modeling & machine learning. 2023;

4. 12. Retinopathy, Neuropathy, and Foot Care: Standards of Care in Diabetes-2024. Diabetes Care [Internet]. 2024 Jan 1 [cited 2025 Apr 14];47(Suppl 1):S231–43. Available from: https://pubmed.ncbi.nlm.nih.gov/38078577/

5. Claxton AJ, Cramer J, Pierce C. A systematic review of the associations between dose regimens and medication compliance. Clin Ther [Internet]. 2001 [cited 2025 Apr 14];23(8):1296–310. Available from: https://pubmed.ncbi.nlm.nih.gov/11558866/

6. Praveena BA, Lokesh N, Buradi A, Santhosh N, Praveena BL, Vignesh R. A comprehensive review of emerging additive manufacturing (3D printing technology): Methods, materials, applications, challenges, trends and future potential. Mater Today Proc. 2022 Jan 1;52:1309–13.

7. Milliken RL, Quinten T, Andersen SK, Lamprou DA. Application of 3D printing in early phase development of pharmaceutical solid dosage forms. Int J Pharm. 2024 Mar 25;653:123902.

8. Bhatkande A, Narala S, Wang H, Narala N, Karnik I, Vemula SK, et al. Extrusion-Based Three-Dimensional Printing of Metronidazole Immediate Release Tablets: Impact of Processing Parameters and in Vitro Evaluation. J Pharm Innov [Internet]. 2024 Dec 1 [cited 2025 Apr 14];19(6):1–11. Available from: https://link.springer.com/article/10.1007/s12247-024-09878-y

9. Holkunde A, Karnik I, Uttreja P, Narala N, Wang H, Elkanayati RM, et al. Personalized Medicine Through Semisolid-Extrusion Based 3D Printing: Dual-Drug Loaded Gummies for Enhanced Patient Compliance. Pharm Res [Internet]. 2025 Jan 1 [cited 2025 Apr 14];42(1):185–201. Available from: https://link.springer.com/article/10.1007/s11095-024-03813-z

10. Dumpa N, Butreddy A, Wang H, Komanduri N, Bandari S, Repka MA. 3D printing in personalized drug delivery: An overview of hot-melt extrusion-based fused deposition modeling. Int J Pharm. 2021 May 1;600:120501.

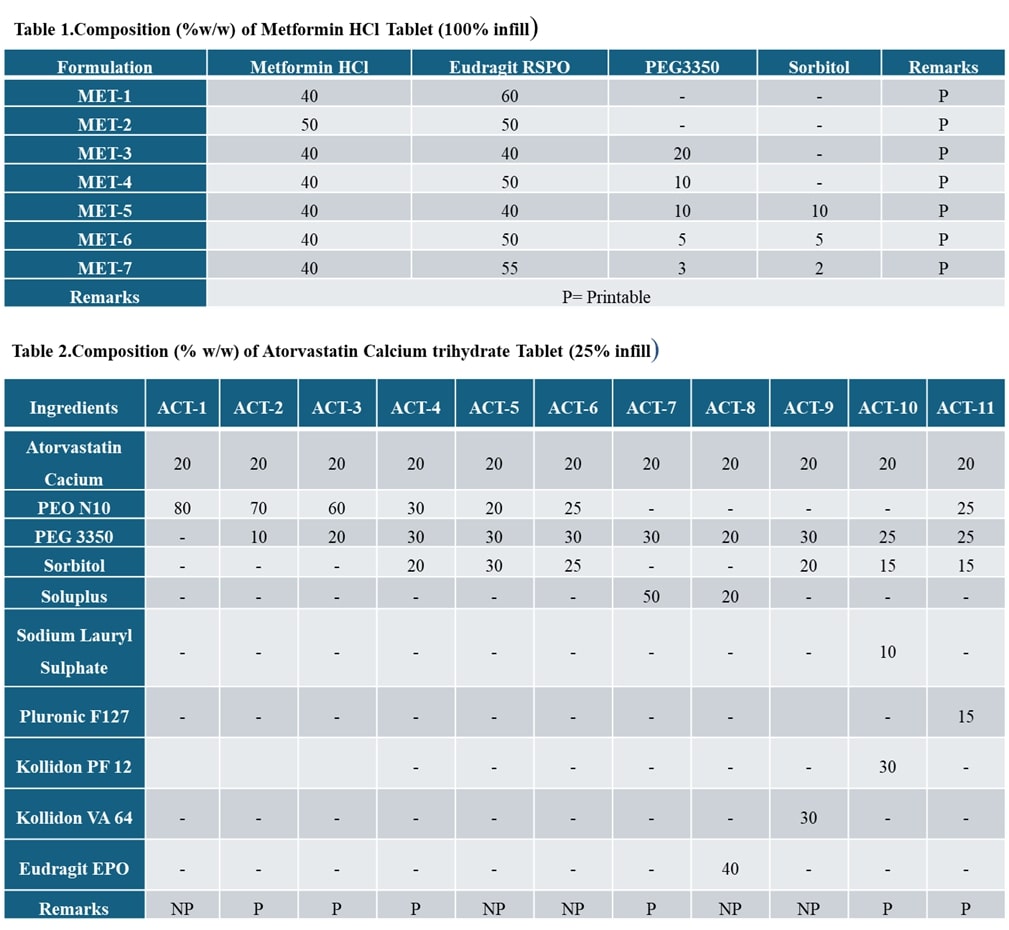

Table 1 and Table 2 display the composition (% w/w) of Metformin HCl and Atorvastatin Calcium trihydrate 3D-printed tablets, respectively, with various excipients and formulation codes.

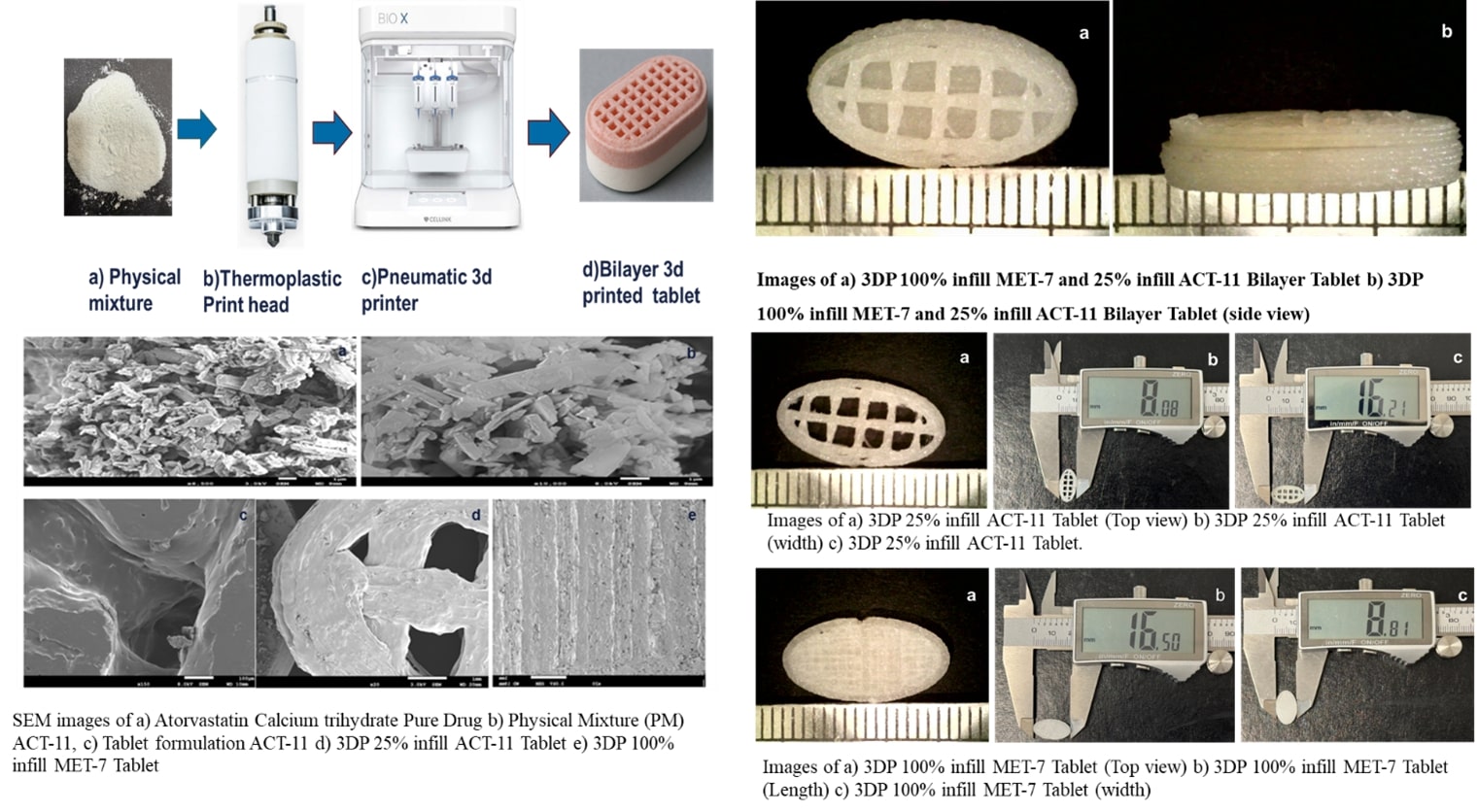

Table 1 and Table 2 display the composition (% w/w) of Metformin HCl and Atorvastatin Calcium trihydrate 3D-printed tablets, respectively, with various excipients and formulation codes. Top left: Schematic workflow illustrating the process from physical mixture preparation to pneumatic 3D printing and resulting bilayer 3D-printed tablet. Top right: Photographs of 3D-printed tablets: (a) Top view and (b) side view of a bilayer tablet composed of 100% infill MET-7 and 25% infill ACT-11 formulations. Middle: SEM images showing surface and cross-sectional morphology of Atorvastatin Calcium trihydrate, physical mixture, tablet formulation, and 3D-printed tablets. Bottom right: Dimensional measurements and top/side views of 3D-printed ACT-11 (top row) and MET-7 (bottom row) tablets, demonstrating size and shape uniformity.

Top left: Schematic workflow illustrating the process from physical mixture preparation to pneumatic 3D printing and resulting bilayer 3D-printed tablet. Top right: Photographs of 3D-printed tablets: (a) Top view and (b) side view of a bilayer tablet composed of 100% infill MET-7 and 25% infill ACT-11 formulations. Middle: SEM images showing surface and cross-sectional morphology of Atorvastatin Calcium trihydrate, physical mixture, tablet formulation, and 3D-printed tablets. Bottom right: Dimensional measurements and top/side views of 3D-printed ACT-11 (top row) and MET-7 (bottom row) tablets, demonstrating size and shape uniformity. Spectral and thermal analysis of tablet formulations: FTIR spectra, DSC thermograms, and pXRD diffractograms compare physical mixtures, pure drugs, and 3D-printed tablets to assess drug-excipient interactions and crystallinity.

Spectral and thermal analysis of tablet formulations: FTIR spectra, DSC thermograms, and pXRD diffractograms compare physical mixtures, pure drugs, and 3D-printed tablets to assess drug-excipient interactions and crystallinity.