Manufacturing and Analytical Characterization - Chemical

(T1330-02-11) Impact of In-Die Compression Behavior on the Sticking Propensity During Tablet Manufacturing: Binary Component Pharmaceutical Systems

- RH

Rahul Haware, Ph.D.

Director

Natoli Scientific

Telford, Pennsylvania, United States - RH

Rahul Haware, Ph.D.

Director

Natoli Scientific

Telford, Pennsylvania, United States - KC

Kerry Cruz

Lab Manager

Natoli Scinetific

Telford, Pennsylvania, United States - RS

Robert Sedlock, MS

Director

Natoli Scinetific

Telford, Pennsylvania, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Methods:

A binary component systems of model predominantly plastic, elastic, and fragmenting material were used. A 50 :50 mixture of plastic-brittle system (Vivapur® 102 and SpheroLac® 100), plastic-elastic system (Vivapur® 102 and Starch 1500®), and brittle-elastic system (Starch 1500® and SpheroLac® 100) were made by blending equal amount of these materials in V-cone blender at 15 rpm for 10 minutes. Helium density value was used to calculate the powder mass to keep a constant particle volume of 0.1913 cm3 in every tablet. The required amount of powder was weighed. This amount was poured manually in a pre-lubricated die with MgSt. A powder was compressed at 100.98 ± 2.09 MPa compression pressure (CP) and at 500 mm/s compression speed using the Direct Simulator Presster. The tablets were made using 10 mm flat-faced punches. An ‘in-die’ material deformation, strength, and compact spring behavior (in-die’ expansion) was evaluated from the obtained continuous compression profile. A material deformation was measured with Heckel yield pressure of plastic deformation (YPpl) and elastic recovery (YPel)[1]. A material and compact strength in the respective compression and decompression phase was measured with compression modulus (CM) and decompression modulus (DCM)[2]. A tablet spring behavior was evaluated with ‘in-die’ elastic recovery and ‘cumulative elastic recovery’[3]. The sticking index (SI), which is a ratio of powder’s wall friction angle to an internal friction, was measured using FT4 rheometer. Various metal coupons like S7, M340, and Natoli Ultracoat were used to measure the powder wall friction angle [4, 5].

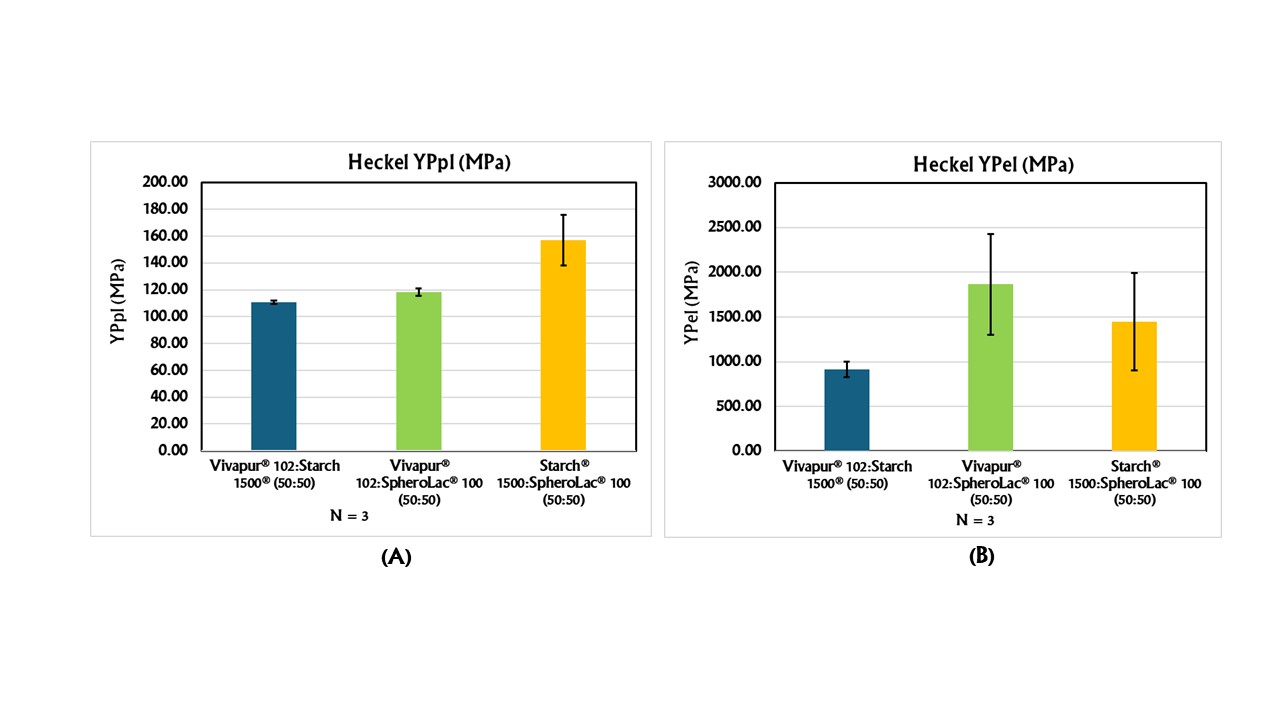

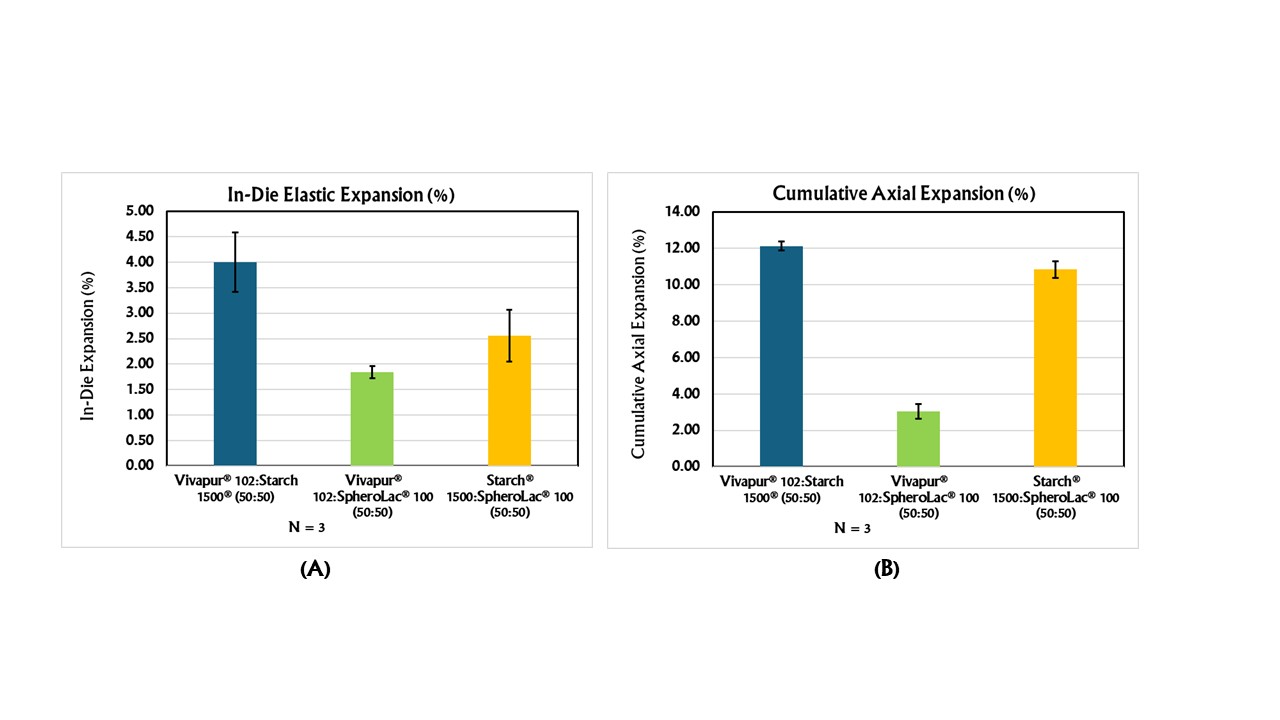

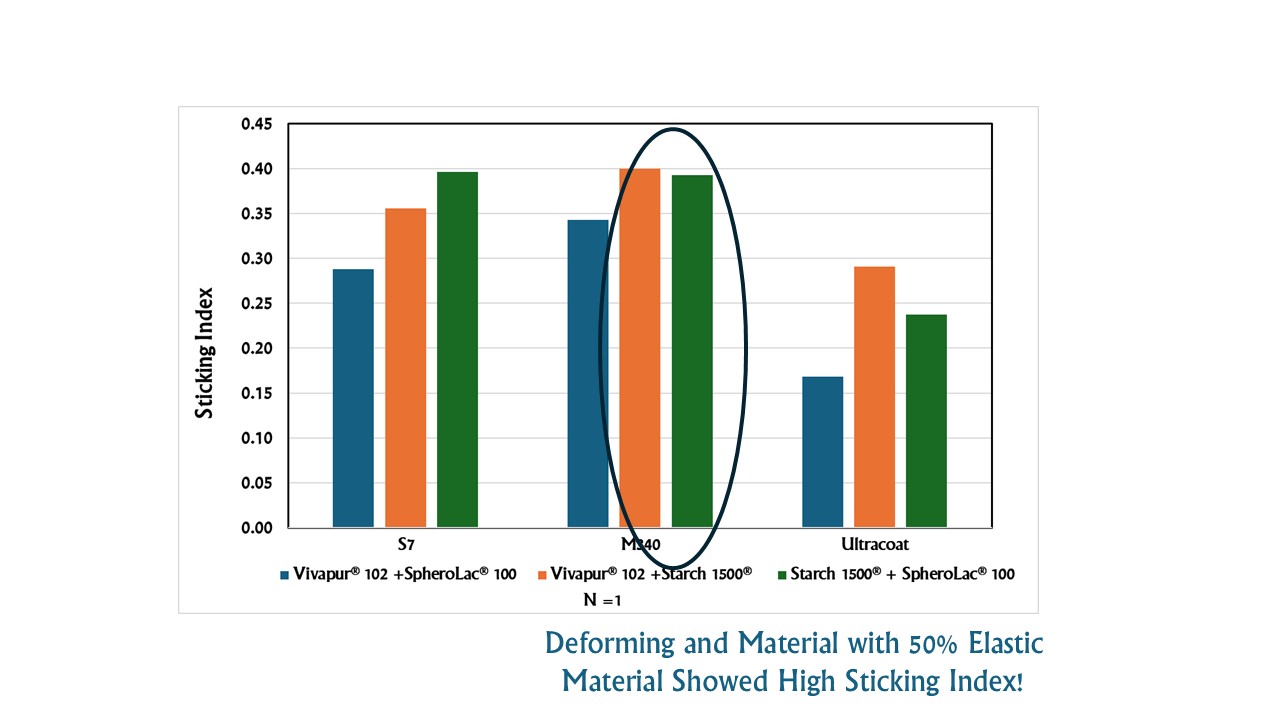

Results: A plastic-elastic system exhibited the lowest YPpl and YPel indicating their high deformation in the compression phase and respective elastic recovery in the decompression phase (Figure 1). A plastic-brittle system showed the highest YPpl and YPel. It insinuates its limited deformation and low elasticity as compared to the plastic-elastic system during the tableting operation. A third brittle-elastic system showed an intermediate YPpl and YPel as compared to other two systems. A plastic-brittle system showed the highest CM and DCM. This could be attributed to hard lactose monohydrate [2]. This could support their limited deformation potential. Both plastic-elastic and elastic-brittle systems interchangeable low or medium CM and DCM depend on the compression and decompression pressure range. A plastic-brittle system and a plastic-elastic system revealed a respective lowest and the highest ‘In-die’ and cumulative axial expansion (Figure 2). In all systems studied, a plastic-brittle system showed medium tablet strength but the lowest SI with all studied metal coupons (Figure 3). Contrary, a plastic-elastic system produced stronger tablets, but had a highest sticking index with M340 and Natoli Ultracoat coupons and medium SI with S7 coupons. An elastic-brittle system was not ablet to make measurable strengths tablets and showed an intermediate SI with M340 and Natoli Ultracoat coupons and highest SI with S7 coupon.

Conclusion: These studies showed a direct relationship between material deformation during the compression phase and its spring behavior (In-die’ tablet expansion) with a computed sticking index. A plastic-elastic system though formed stronger tablets; it showed highest possible tablet sticking propensity. On the other hand, a plastic-brittle system formed weaker tablets than later but insinuated lowest sticking tendency. Certainly, monitoring and controlling material deformation in the compression phase could reduce decompression phase spring behavior and subsequent tablet sticking propensity.

References: 1. Haware, R.V., I. Tho, and A. Bauer-Brandl, Application of multivariate methods to compression behavior evaluation of directly compressible materials. European Journal of Pharmaceutics and Biopharmaceutics, 2009. 72(1): p. 148-155.

2. Patel, D.B., et al., Compression–decompression modulus (CDM) – an alternative/complementary approach to Heckel’s analysis. Pharmaceutical Development and Technology, 2022. 27(7): p. 805-815.

3. Haware, R.V., I. Tho, and A. Bauer-Brandl, Evaluation of a rapid approximation method for the elastic recovery of tablets. Powder Technology, 2010. 202(1): p. 71-77.

4. Nakamura, S., et al., Predicting the Occurrence of Sticking during Tablet Production by Shear Testing of a Pharmaceutical Powder. Chem Pharm Bull (Tokyo), 2016. 64(5): p. 512-6.

5. D. Patel, K.C., R. Sedlock, R. Haware, Powder Rheology: Gateway for Tablet Sticking Insights, in Manufacturing Chemist. 2021, HPCi Media Limited: Shrewsbury, UK.

Acknowledgements: Authors do not have any conflict of interest. Figure 1 Heckel (A) YPpl and (B) YPel of plastic-elastic, plastic-brittle, and elastic-brittle binary systems

Figure 1 Heckel (A) YPpl and (B) YPel of plastic-elastic, plastic-brittle, and elastic-brittle binary systems Figure 2 Spring behavior (A) 'In-Die' expansion (%); (B) Cumulative elastic recovery (%) of plastic-elastic, plastic-brittle, and elastic-brittle binary systems

Figure 2 Spring behavior (A) 'In-Die' expansion (%); (B) Cumulative elastic recovery (%) of plastic-elastic, plastic-brittle, and elastic-brittle binary systems Figure 3 Sticking index of plastic-elastic, plastic-brittle, and elastic-brittle binary systems

Figure 3 Sticking index of plastic-elastic, plastic-brittle, and elastic-brittle binary systems