Manufacturing and Analytical Characterization - Chemical

(T1130-02-12) Why Rheology Matters: Insights into Granulation Behavior in Twin-Screw Melt Granulation

Tuesday, November 11, 2025

11:30 AM - 12:30 PM CT

- NK

Niyati Niranjan Kodange, MS

Graduate Research Assistant

University of Texas at Austin

Austin, Texas, United States - NK

Niyati Niranjan Kodange, MS

Graduate Research Assistant

University of Texas at Austin

Austin, Texas, United States

Fengyuan Yang, PhD

Principal Scientist

Ashland Specialty Ingredients

Wilmington, Delaware, United States- AA

Albert Alexander

Staff Scientist, Pharma OSD

Ashland Specialty Ingredients

Wilmington, Delaware, United States

Kapish Karan, MS

Global OSD Leader

Ashland Specialty Ingredients

Wilmington, Delaware, United States.jpg)

Feng Zhang, Ph.D.

Associate Professor

University of Texas at Austin

Austin, Texas, United States

Presenting Author(s)

Main Author(s)

Co-Author(s)

Purpose: Twin-screw melt granulation (TSMG) is a solvent-free, continuous manufacturing process that produces granules without additional drying step. It employs a thermal binder that softens at elevated temperatures to form solid bridges between drug particles, enabling granule formation. Powder rheology within the extruder significantly influences granulation by affecting material packing, represented by the Q/N ratio (feed rate to screw speed). An increased Q/N ratio corresponds to a higher degree of barrel fill, leading to greater compaction within the kneading zones. Powder rheology can be assessed through powder cohesion/ internal friction and powder-wall friction. Binder rheology, particularly its viscoelastic behavior quantified by the loss factor (tan δ), also plays a key role. Binder softening and distribution govern nucleation and granule growth. This study aims to examine how both powder and binder rheology affect TSMG performance. Silica, a common glidant, was added at varying levels to alter powder flow characteristics. By investigating these factors, the study emphasizes the need to simultaneously optimize both powder and binder rheological properties to ensure robust, consistent granulation outcomes.

Methods: 5% Klucel FusionTM X (hydroxypropyl cellulose/ HPC) is used as a binder and Acetaminophen (APAP, d90= 47 µm) is used as a model drug. Silica/Aerosil® 200 (0.05 -1% w/w) was added to modulate powder flow. Granulation was performed using a Leistritz® ZSE 18-HPe co-rotating twin-screw extruder (25 L/D) equipped with a 15 mm kneading block (5 mm disc width, 0.1mm overflight clearance and 90º staggering angle) near the barrel end. Two Q/N levels (0.025 and 0.033 Kg.hr-1.rpm-1) were studied by varying screw speed (100 and 75 rpm) at a constant feed rate of 2.5 Kg.hr-1. Granule temperature was measured radiometrically using a Teledyne FLIR E54 camera and processed via Thermal Studio ProTM software. Granule size was analyzed with CamSizer®. Tabletability was assessed by compressing granules using a hydraulic press and determining tensile strength. Binder’s viscoelasticity (tan δ), with and without silica, was evaluated using an Anton Paar MCR 301 rheometer. Powder rheology was determined using a Brookfield Powder Flow Tester (PFT).

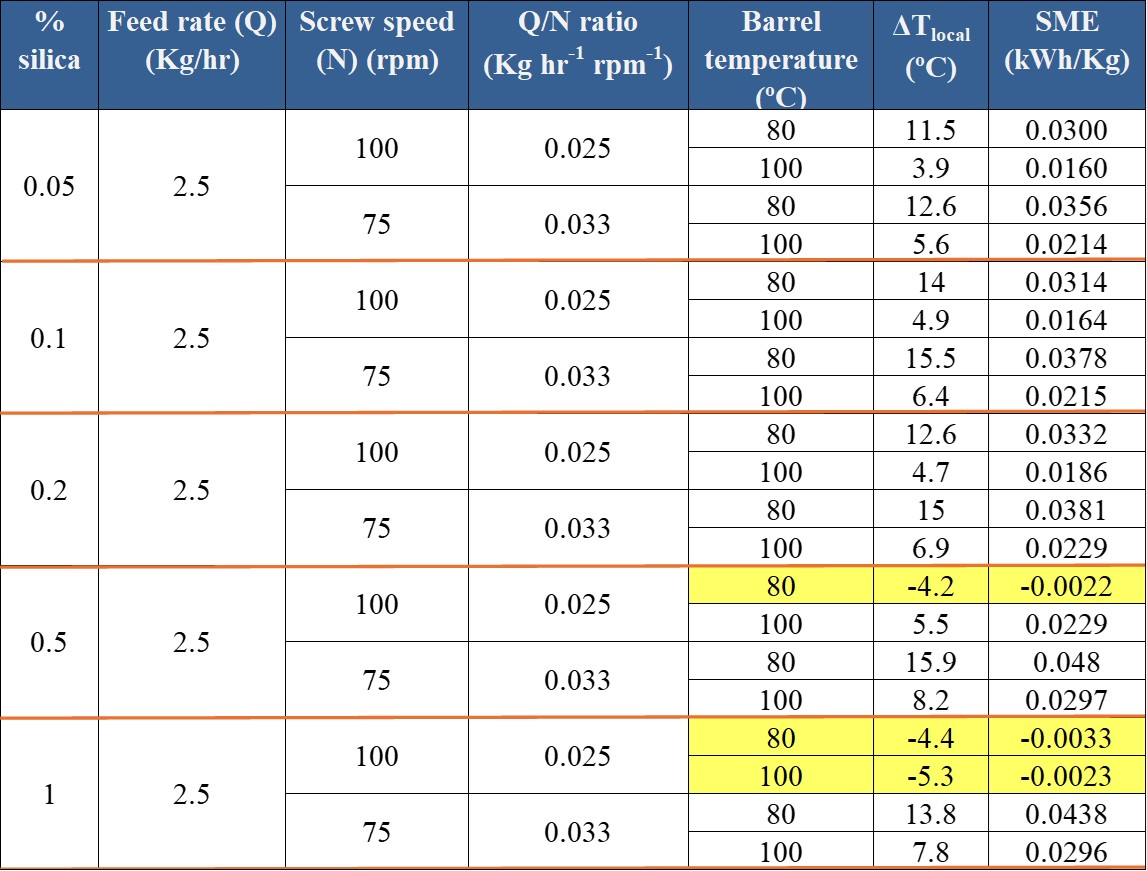

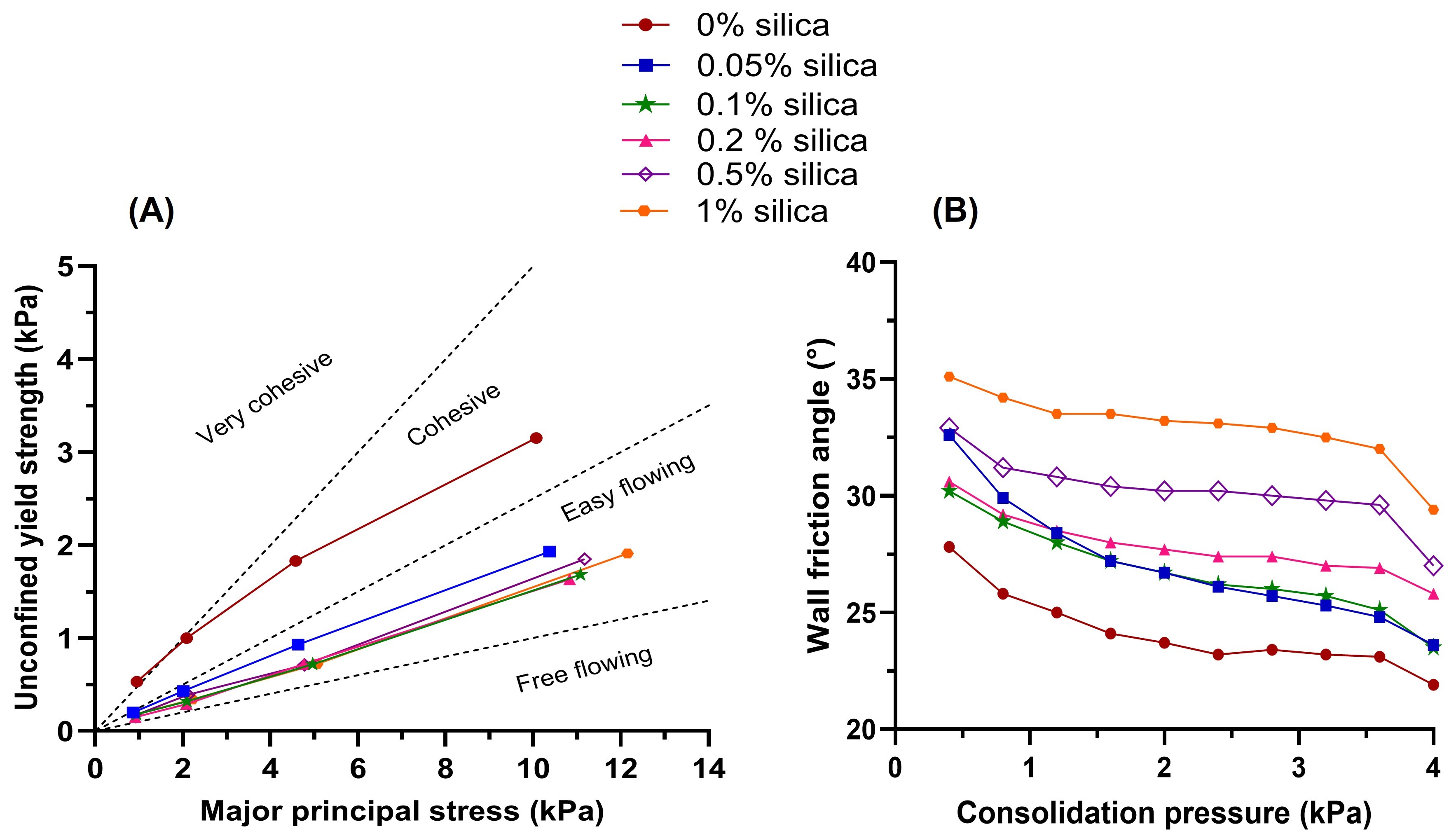

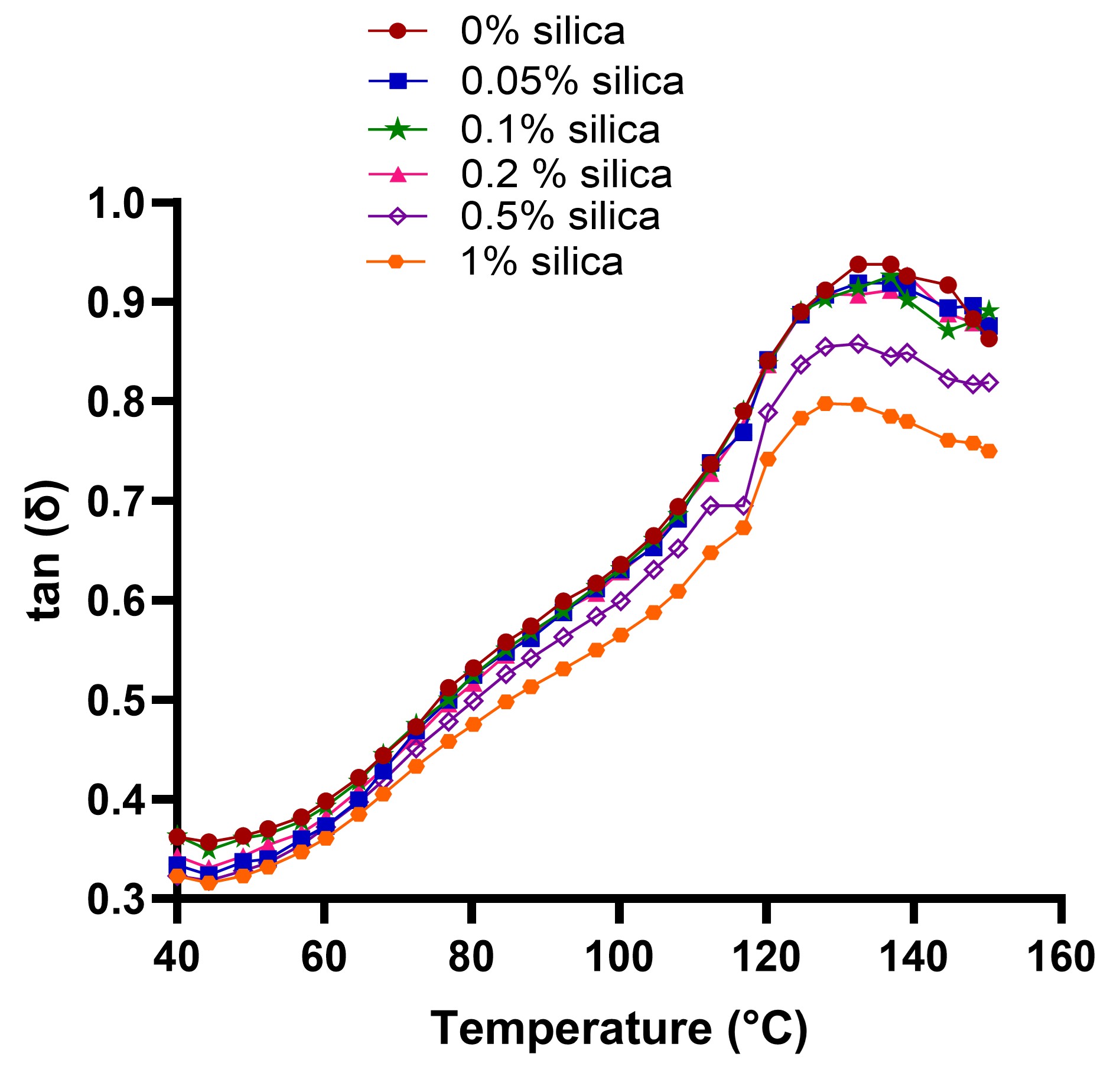

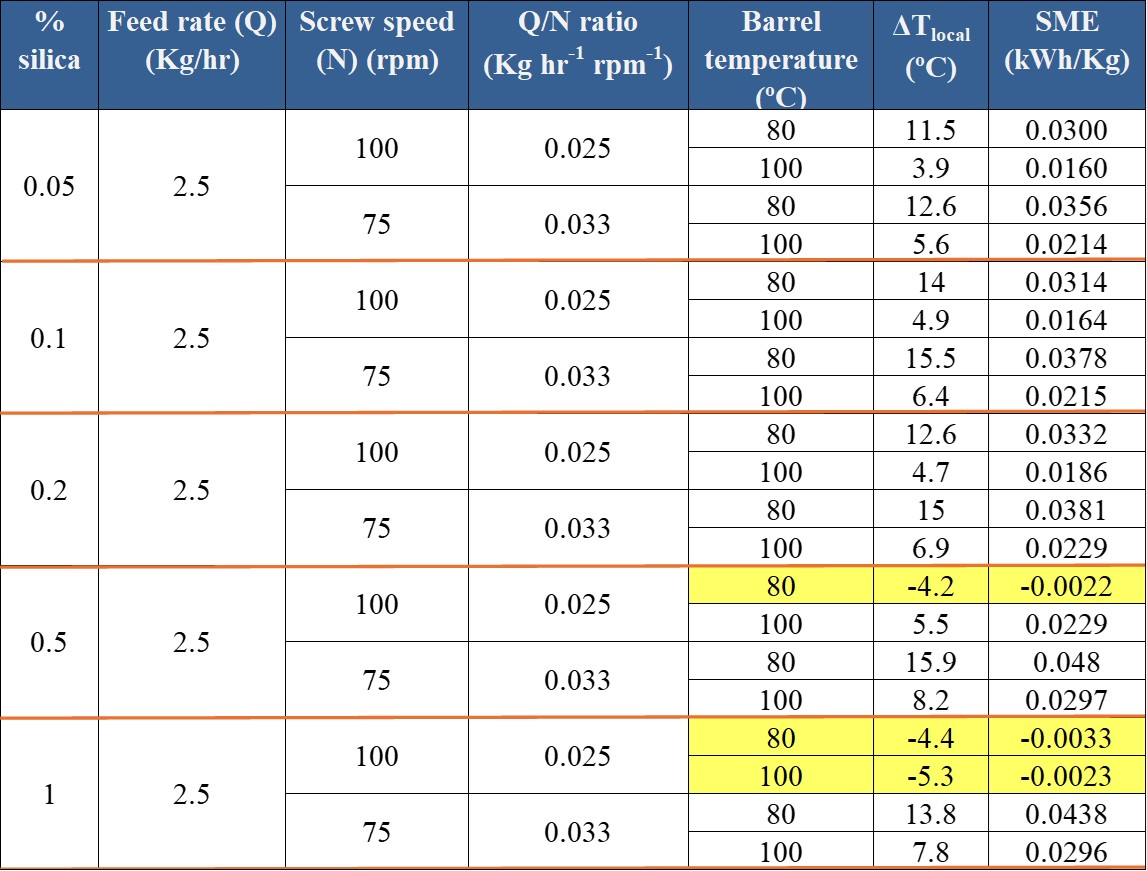

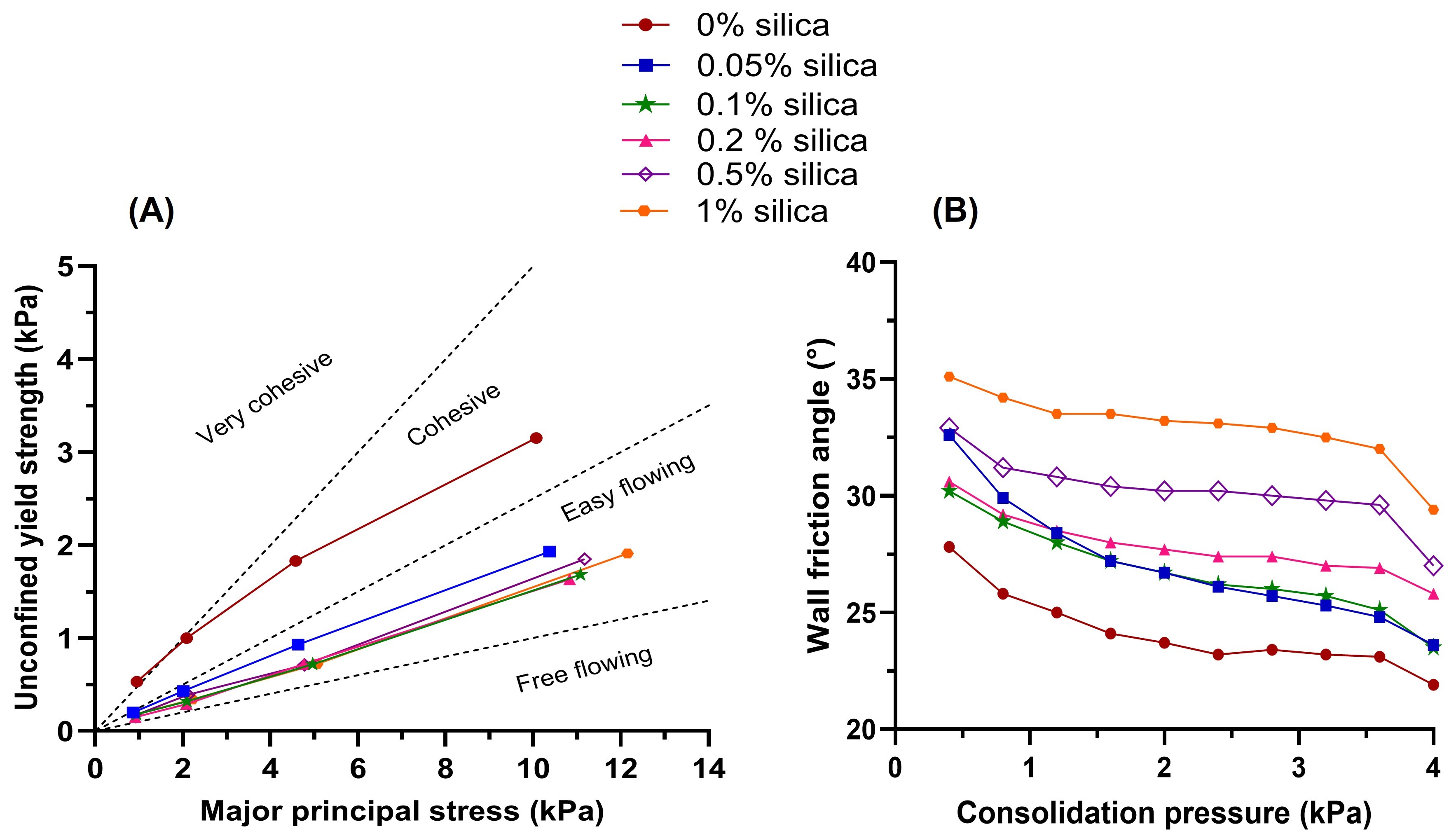

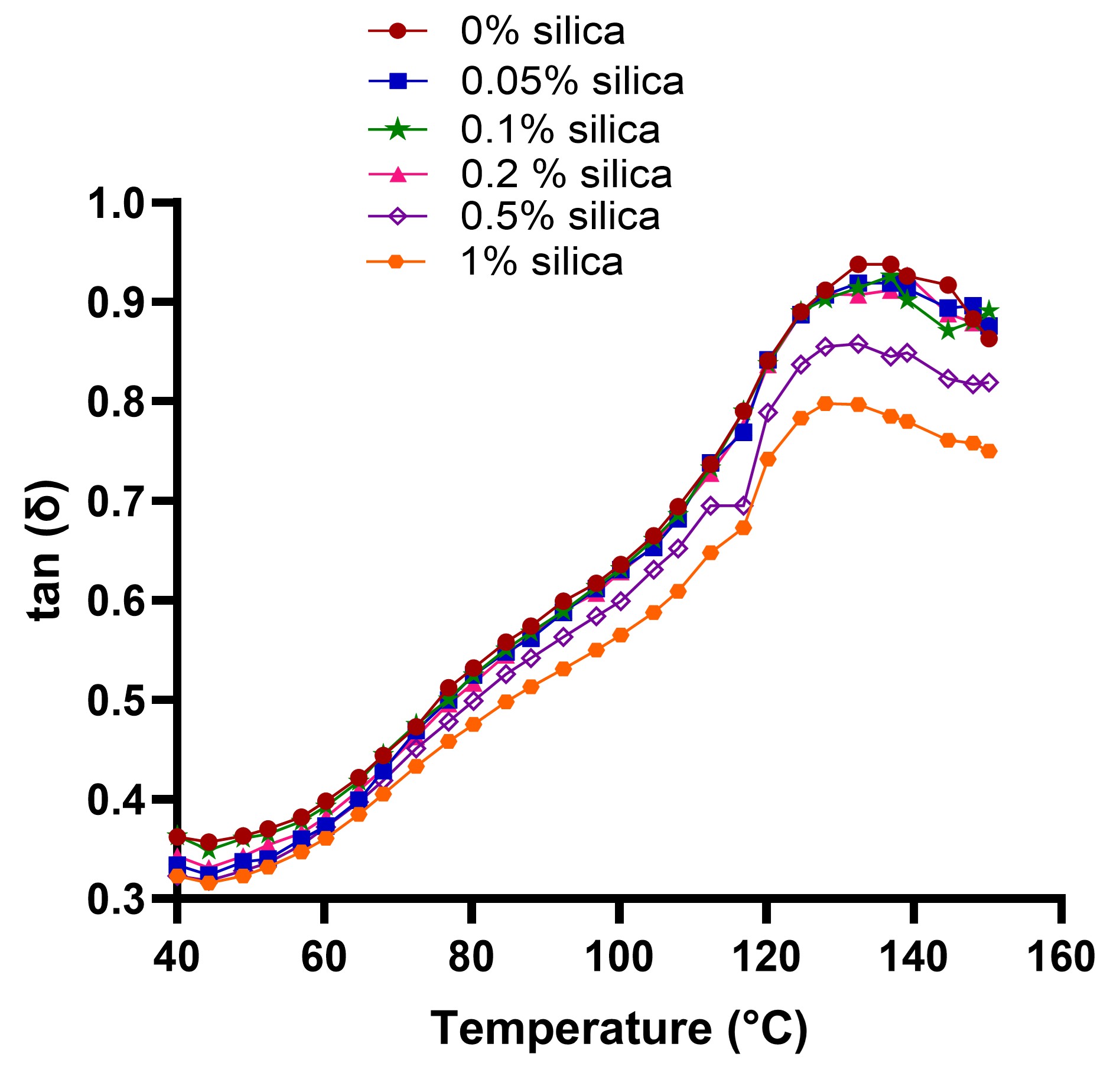

Results: Silica was added to improve the flow of powder blend. Varying levels of silica were added to demonstrate different powder rheology and understand its impact on granulation behavior. Granulation outcomes for blends containing 95% APAP and 5% HPC at different silica levels are summarized in Table 1. Successful granulation was defined by granule growth [ < 20% fines ( < 150 µm)] and tablet tensile strengths of ≥ 2 MPa. For a blend containing 0.5% silica, granule growth was not observed at a Q/N ratio of 0.025 Kg.hr-1.rpm-1 and a barrel temperature of 80ºC. Similarly, for 1% silica, granulation failed at the same Q/N ratio across both barrel temperatures. In these cases, successful granulation required a higher Q/N ratio of 0.033 Kg.hr-1.rpm-1. Since the Q/N ratio reflects the degree of fill, a higher ratio indicates greater material packing, which enhances drug-binder interactions and increases the apparent viscosity of the material at kneading zone, resulting in greater viscous heat dissipation and promoting granule growth. As shown in Figures 1 and 2, increasing silica levels influenced both powder and binder rheology. Powder rheology was assessed via unconfined yield strength (UYS), indicating powder’s cohesiveness and internal friction, and wall friction angle (WFA), representing powder-wall friction. Higher UYS indicates poor flowability while higher WFA represents increased powder-wall friction. Silica addition reduced UYS, suggesting improved flowability, but this effect plateaued beyond 0.1% (Figure 1A). Conversely, WFA increased with silica level, indicating elevated friction at the powder-wall interface (Figure 1B). Binder rheology, represented by tan (δ), indicates binder deformability, which influences its softening and distribution around drug particles. As shown in Figure 3, tan (δ) remained unchanged up to 0.2% silica but decreased at 0.5% and 1% silica level, suggesting reduced binder deformability. As binder softening is critical for granule growth, the impaired softening at higher silica levels necessitated granulation under high Q/N ratios (Table 1). To understand the impact of rheology on local heat (ΔTlocal) and specific mechanical energy (SME) under identical processing conditions, granulation was performed at both Q/N ratios across all silica levels (Table 1). The higher silica levels (0.5-1%) were associated with increased SME, correlating with elevated WFA and reduced tan (δ) at the same Q/N ratio of 0.033 Kg.hr-1.rpm-1. These findings suggest that 0.1% silica is optimal, as it improves powder flow without affecting binder softening or increasing wall friction, supporting efficient and consistent granulation.

Conclusion: Varying silica concentrations altered the rheological properties of both powder and binder, affecting granulation performance in TSMG. Powder flowability improved up to 0.1% silica, with no added benefit beyond this level. Higher levels (0.5–1%) impaired binder softening and increased powder-wall friction, resulting in elevated SME at the same Q/N ratio. These results underscore the importance of evaluating both powder and binder rheology to understand and optimize TSMG outcomes.

References: 1. Kodange, N.N., Pradhan, A., Yang, F., Karan, K., Schwing, Q., Durig, T., Zhang, F., 2025. Unraveling local heat generation in twin-screw melt granulation. International Journal of Pharmaceutics 675, 125563.

2. Monteyne, T., Heeze, L., Mortier, S.T.F., Oldörp, K., Nopens, I., Remon, J.-P., Vervaet, C., De Beer, T., 2016. The use of rheology to elucidate the granulation mechanisms of a miscible and immiscible system during continuous twin-screw melt granulation. International journal of pharmaceutics 510, 271-284.

3. Liu, T., Paul, S., Beeson, B.T., Alexander, J., Yang, F., Bi, V., Durig, T., Sun, C.C., Zhang, F., 2020. Effect of hydroxypropyl cellulose level on twin-screw melt granulation of acetaminophen. Aaps Pharmscitech 21, 1-14.

Acknowledgements: This work is funded and supported by Ashland Specialty Ingredients, Wilmington, Delaware

Table 1: Granulations runs at different silica levels and processing conditions with its corresponding ΔTlocal and SME (runs where granule growth was not observed are highlighted in yellow).

Table 1: Granulations runs at different silica levels and processing conditions with its corresponding ΔTlocal and SME (runs where granule growth was not observed are highlighted in yellow).

Figure 1: Powder rheology of 95%APAP and 5% Klucel FusionTM X HPC blend containing different levels of silica- A) Unconfined yield strength of powder blend represents the powder’s cohesive strength and internal friction and B) Wall friction angle (WFA) represents the powder-wall friction.

Figure 1: Powder rheology of 95%APAP and 5% Klucel FusionTM X HPC blend containing different levels of silica- A) Unconfined yield strength of powder blend represents the powder’s cohesive strength and internal friction and B) Wall friction angle (WFA) represents the powder-wall friction.

Figure 2: Tan (δ) values as a function of temperature for Klucel FusionTM X HPC at different silica levels. Temperature ramps were performed from 40 ºC to 150 ºC in controlled deformation oscillation mode with a shear strain amplitude of 0.01% and angular frequency of 6.283 rad/s.

Figure 2: Tan (δ) values as a function of temperature for Klucel FusionTM X HPC at different silica levels. Temperature ramps were performed from 40 ºC to 150 ºC in controlled deformation oscillation mode with a shear strain amplitude of 0.01% and angular frequency of 6.283 rad/s.

Methods: 5% Klucel FusionTM X (hydroxypropyl cellulose/ HPC) is used as a binder and Acetaminophen (APAP, d90= 47 µm) is used as a model drug. Silica/Aerosil® 200 (0.05 -1% w/w) was added to modulate powder flow. Granulation was performed using a Leistritz® ZSE 18-HPe co-rotating twin-screw extruder (25 L/D) equipped with a 15 mm kneading block (5 mm disc width, 0.1mm overflight clearance and 90º staggering angle) near the barrel end. Two Q/N levels (0.025 and 0.033 Kg.hr-1.rpm-1) were studied by varying screw speed (100 and 75 rpm) at a constant feed rate of 2.5 Kg.hr-1. Granule temperature was measured radiometrically using a Teledyne FLIR E54 camera and processed via Thermal Studio ProTM software. Granule size was analyzed with CamSizer®. Tabletability was assessed by compressing granules using a hydraulic press and determining tensile strength. Binder’s viscoelasticity (tan δ), with and without silica, was evaluated using an Anton Paar MCR 301 rheometer. Powder rheology was determined using a Brookfield Powder Flow Tester (PFT).

Results: Silica was added to improve the flow of powder blend. Varying levels of silica were added to demonstrate different powder rheology and understand its impact on granulation behavior. Granulation outcomes for blends containing 95% APAP and 5% HPC at different silica levels are summarized in Table 1. Successful granulation was defined by granule growth [ < 20% fines ( < 150 µm)] and tablet tensile strengths of ≥ 2 MPa. For a blend containing 0.5% silica, granule growth was not observed at a Q/N ratio of 0.025 Kg.hr-1.rpm-1 and a barrel temperature of 80ºC. Similarly, for 1% silica, granulation failed at the same Q/N ratio across both barrel temperatures. In these cases, successful granulation required a higher Q/N ratio of 0.033 Kg.hr-1.rpm-1. Since the Q/N ratio reflects the degree of fill, a higher ratio indicates greater material packing, which enhances drug-binder interactions and increases the apparent viscosity of the material at kneading zone, resulting in greater viscous heat dissipation and promoting granule growth. As shown in Figures 1 and 2, increasing silica levels influenced both powder and binder rheology. Powder rheology was assessed via unconfined yield strength (UYS), indicating powder’s cohesiveness and internal friction, and wall friction angle (WFA), representing powder-wall friction. Higher UYS indicates poor flowability while higher WFA represents increased powder-wall friction. Silica addition reduced UYS, suggesting improved flowability, but this effect plateaued beyond 0.1% (Figure 1A). Conversely, WFA increased with silica level, indicating elevated friction at the powder-wall interface (Figure 1B). Binder rheology, represented by tan (δ), indicates binder deformability, which influences its softening and distribution around drug particles. As shown in Figure 3, tan (δ) remained unchanged up to 0.2% silica but decreased at 0.5% and 1% silica level, suggesting reduced binder deformability. As binder softening is critical for granule growth, the impaired softening at higher silica levels necessitated granulation under high Q/N ratios (Table 1). To understand the impact of rheology on local heat (ΔTlocal) and specific mechanical energy (SME) under identical processing conditions, granulation was performed at both Q/N ratios across all silica levels (Table 1). The higher silica levels (0.5-1%) were associated with increased SME, correlating with elevated WFA and reduced tan (δ) at the same Q/N ratio of 0.033 Kg.hr-1.rpm-1. These findings suggest that 0.1% silica is optimal, as it improves powder flow without affecting binder softening or increasing wall friction, supporting efficient and consistent granulation.

Conclusion: Varying silica concentrations altered the rheological properties of both powder and binder, affecting granulation performance in TSMG. Powder flowability improved up to 0.1% silica, with no added benefit beyond this level. Higher levels (0.5–1%) impaired binder softening and increased powder-wall friction, resulting in elevated SME at the same Q/N ratio. These results underscore the importance of evaluating both powder and binder rheology to understand and optimize TSMG outcomes.

References: 1. Kodange, N.N., Pradhan, A., Yang, F., Karan, K., Schwing, Q., Durig, T., Zhang, F., 2025. Unraveling local heat generation in twin-screw melt granulation. International Journal of Pharmaceutics 675, 125563.

2. Monteyne, T., Heeze, L., Mortier, S.T.F., Oldörp, K., Nopens, I., Remon, J.-P., Vervaet, C., De Beer, T., 2016. The use of rheology to elucidate the granulation mechanisms of a miscible and immiscible system during continuous twin-screw melt granulation. International journal of pharmaceutics 510, 271-284.

3. Liu, T., Paul, S., Beeson, B.T., Alexander, J., Yang, F., Bi, V., Durig, T., Sun, C.C., Zhang, F., 2020. Effect of hydroxypropyl cellulose level on twin-screw melt granulation of acetaminophen. Aaps Pharmscitech 21, 1-14.

Acknowledgements: This work is funded and supported by Ashland Specialty Ingredients, Wilmington, Delaware

Table 1: Granulations runs at different silica levels and processing conditions with its corresponding ΔTlocal and SME (runs where granule growth was not observed are highlighted in yellow).

Table 1: Granulations runs at different silica levels and processing conditions with its corresponding ΔTlocal and SME (runs where granule growth was not observed are highlighted in yellow). Figure 1: Powder rheology of 95%APAP and 5% Klucel FusionTM X HPC blend containing different levels of silica- A) Unconfined yield strength of powder blend represents the powder’s cohesive strength and internal friction and B) Wall friction angle (WFA) represents the powder-wall friction.

Figure 1: Powder rheology of 95%APAP and 5% Klucel FusionTM X HPC blend containing different levels of silica- A) Unconfined yield strength of powder blend represents the powder’s cohesive strength and internal friction and B) Wall friction angle (WFA) represents the powder-wall friction. Figure 2: Tan (δ) values as a function of temperature for Klucel FusionTM X HPC at different silica levels. Temperature ramps were performed from 40 ºC to 150 ºC in controlled deformation oscillation mode with a shear strain amplitude of 0.01% and angular frequency of 6.283 rad/s.

Figure 2: Tan (δ) values as a function of temperature for Klucel FusionTM X HPC at different silica levels. Temperature ramps were performed from 40 ºC to 150 ºC in controlled deformation oscillation mode with a shear strain amplitude of 0.01% and angular frequency of 6.283 rad/s.